Gaomi Tongyu Shoes Co. Ltd is a professional manufacturer of direct injected safety shoes. Every model of our product has been researched and developed by professional staff, and has been tested by lab before production process. We use wider toe cap for superior fitting and impact resistant, imported quality leather for upper breathability, direct injection machine and full range of testing equipment to ensure our production and quality is in conformity with international standards. Our company has been certified with ISO-9001,45001,14001,BSCI,CSA,Sedex,Benchmark,LA etc and all our main products have been granted with CE certificate.

Our company sticks to its purpose of "always be honest people and always keep down-to-earth work style." And we're dedicated to offering superior quality products to ensure our end users are working with a pair of safe and comfortable safety shoes. We have set up a good image to our clients because of our reliable quality, strict management and experienced techniques.

Our Location

Our factory is located in Gaomi City, Shandong province and it is 60km from the Qingdao Airport.

Our History

In the year of 2001, we started the production of safety shoes made by stroble construction using Chinese PU pouring machine lines and export mainly to the Middle Eastern market.

In 2014, Tongyu became the first to introduce direct injection machine in Shandong province. And soon after it we stopped investing any more pouring lines when we found the product physical property and quality made of direct injection machine is superior to pouring construction.

In 2018, We have introduced our 2nd 30 station direct injection machine line with ABB roughing hand. And in order to achieve a higher level of quality, we signed cooperation contract with BASF, and we then became the first factory to use BASF PU for safety shoes in Shandong Province.

In 2023 and 2024,as the capacity requirments we introduced another two 30 station injection machine line with ABB roughing hand and one cements line,to meet more and more clients capacity requirments and totally we have 4 directly injection line and one cements line.

Our Market & Turnover

From 1st January 2024 to 1st January 2025, our direct export turnover reached usd 10,000,000, As the dominate supplier of Skechers,with stable production and good quality control ,recognized by more and more clients,and our main market is European,UK,USA ,Southeast Asia,New zealand,Australian etc.

Our Capacity

Currently, our annual production volume is 1,000,000 pairs; 200 employees; our monthly capacity of uppers are 90,000 pairs made by our own workers; own factory floor area 12,000㎡.

Our Machinery

We have one dual density PU pouring line and four DSM injection machine line with ABB robot,also introduced the new cements line at end of 2024. We have 100 computerized stitching machines, and 3 fully automatic cutting machine (2 machine for cutting leather and 1 machine for cutting lining material).

Our Expertise

With have 20+ years of experience, we have developed a professional and responsive team with strong R&D and management. All our production materials are tested according to CE norm.

Our Materials

BASF/Huafeng PU/PU, PU/TPU, PU/RB; steel toecap, fiberglass toecap, stainless steel soleplate, PS Kevlar insole; cow grain leather, cow nubuck, cow crazy horse,buff grain, buff split; Mesh/Sandwich lining, bronze eyelet, PU /Hi-poly footbed etc.

Our lab. Room

We have our internal lab.room with full range testing equipment for conducting the raw material testing(like tear strength,abrasion resistant,Penetration resistant etc) before we used for mass production for every PO and also have all the testing(ESD,Impact resistance,compression resistant,electric shock resistance ,WR etc)for the shoes from per PO for records before the shipment.With stable strategic partnership with Intertek and SGS,in order to give us more and more professional knowledge to serve customers well.

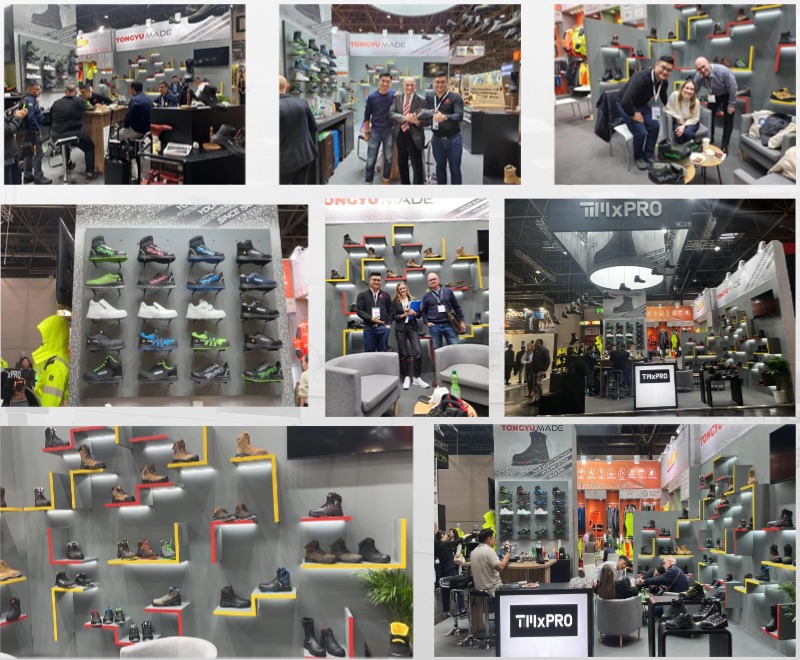

2023 GERMANY A+A EXHIBITION MOMENT

Build a Partnership!

Email: lynn@safetyshoes.cn

Gaomi Tongyu Shoes Co., Ltd.

No. 2688 Shengquan Street, Gaomi City, Shandong Province, 261500 China

Tel: 0536-2334666 Fax: 0536-2322909

Gaomi Tongyu Shoes Co. Ltd is a professional manufacturer of direct injected safety shoes. Every model of our product has been researched and developed by professional staff, and has been tested by lab before production process. We use wider toe cap for superior fitting and impact resistant, imported quality leather for upper breathability, direct injection machine and full range of testing equipment to ensure our production and quality is in conformity with international standards. Our company has been certified with ISO-9001,45001,14001,BSCI,CSA,Sedex,Benchmark,LA etc and all our main products have been granted with CE certificate.

Our company sticks to its purpose of "always be honest people and always keep down-to-earth work style." And we're dedicated to offering superior quality products to ensure our end users are working with a pair of safe and comfortable safety shoes. We have set up a good image to our clients because of our reliable quality, strict management and experienced techniques.

Our Location

Our factory is located in Gaomi City, Shandong province and it is 60km from the Qingdao Airport.

Our History

In the year of 2001, we started the production of safety shoes made by stroble construction using Chinese PU pouring machine lines and export mainly to the Middle Eastern market.

In 2014, Tongyu became the first to introduce direct injection machine in Shandong province. And soon after it we stopped investing any more pouring lines when we found the product physical property and quality made of direct injection machine is superior to pouring construction.

In 2018, We have introduced our 2nd 30 station direct injection machine line with ABB roughing hand. And in order to achieve a higher level of quality, we signed cooperation contract with BASF, and we then became the first factory to use BASF PU for safety shoes in Shandong Province.

In 2023 and 2024,as the capacity requirments we introduced another two 30 station injection machine line with ABB roughing hand and one cements line,to meet more and more clients capacity requirments and totally we have 4 directly injection line and one cements line.

Our Market & Turnover

From 1st January 2024 to 1st January 2025, our direct export turnover reached usd 10,000,000, As the dominate supplier of Skechers,with stable production and good quality control ,recognized by more and more clients,and our main market is European,UK,USA ,Southeast Asia,New zealand,Australian etc.

Our Capacity

Currently, our annual production volume is 1,000,000 pairs; 200 employees; our monthly capacity of uppers are 90,000 pairs made by our own workers; own factory floor area 12,000㎡.

Our Machinery

We have one dual density PU pouring line and four DSM injection machine line with ABB robot,also introduced the new cements line at end of 2024. We have 100 computerized stitching machines, and 3 fully automatic cutting machine (2 machine for cutting leather and 1 machine for cutting lining material).

Our Expertise

With have 20+ years of experience, we have developed a professional and responsive team with strong R&D and management. All our production materials are tested according to CE norm.

Our Materials

BASF/Huafeng PU/PU, PU/TPU, PU/RB; steel toecap, fiberglass toecap, stainless steel soleplate, PS Kevlar insole; cow grain leather, cow nubuck, cow crazy horse,buff grain, buff split; Mesh/Sandwich lining, bronze eyelet, PU /Hi-poly footbed etc.

Our lab. Room

We have our internal lab.room with full range testing equipment for conducting the raw material testing(like tear strength,abrasion resistant,Penetration resistant etc) before we used for mass production for every PO and also have all the testing(ESD,Impact resistance,compression resistant,electric shock resistance ,WR etc)for the shoes from per PO for records before the shipment.With stable strategic partnership with Intertek and SGS,in order to give us more and more professional knowledge to serve customers well.

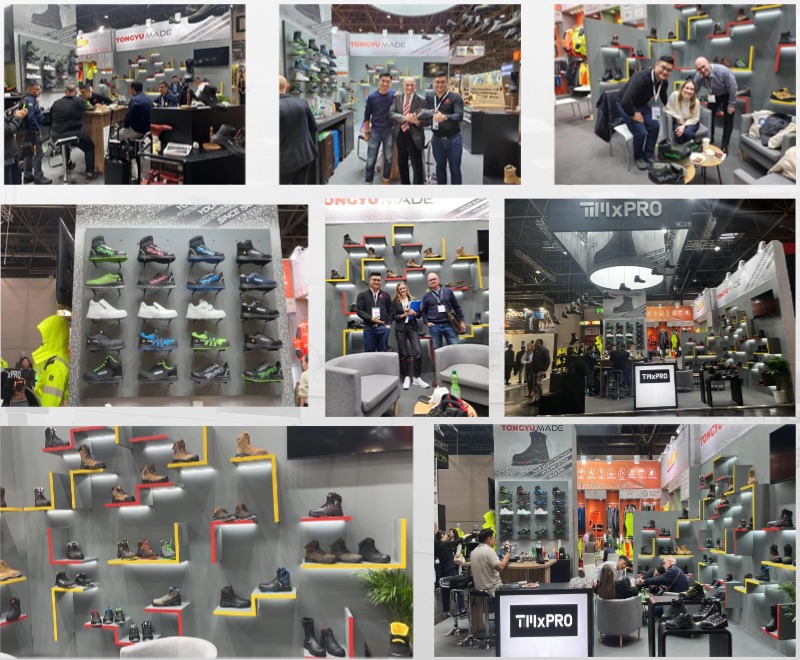

2023 GERMANY A+A EXHIBITION MOMENT

Build a Partnership!

Email: lynn@safetyshoes.cn

Gaomi Tongyu Shoes Co., Ltd.

No. 2688 Shengquan Street, Gaomi City, Shandong Province, 261500 China

Tel: 0536-2334666 Fax: 0536-2322909